What is an Industrial Degreaser? A Complete Guide

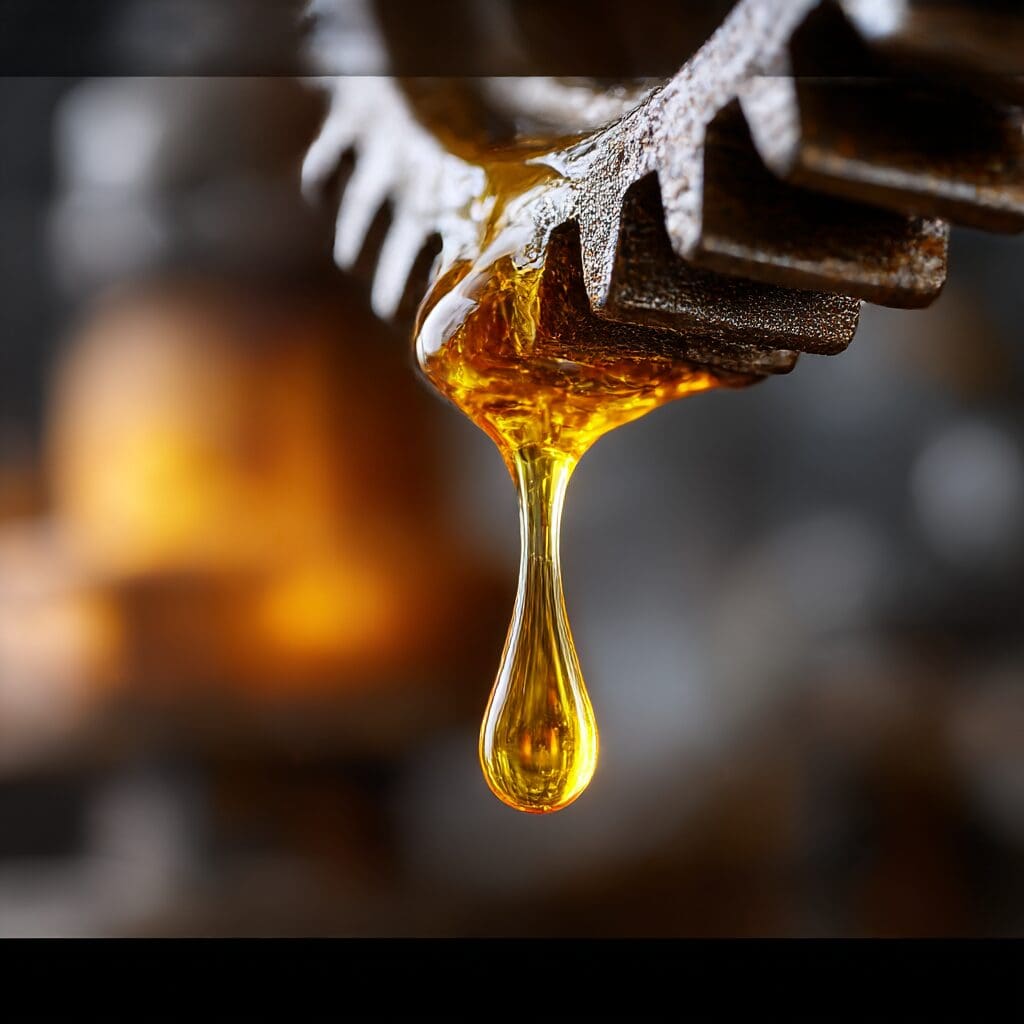

In manufacturing plants, auto shops, food processing facilities, and countless other industrial settings, one challenge remains constant: the accumulation of grease, oil, and stubborn residues on equipment, floors, and machinery. Regular household cleaners simply can’t handle these heavy-duty jobs. This is where industrial degreasers come in—specialized cleaning solutions designed to tackle the toughest grease and oil buildup that would overwhelm conventional cleaners.

Understanding Industrial Degreasers

An industrial degreaser is a powerful cleaning agent formulated specifically to break down and remove heavy accumulations of grease, oil, lubricants, and other petroleum-based substances from industrial equipment, machinery, floors, and work surfaces. Unlike all-purpose cleaners designed for light household cleaning, industrial degreasers are engineered to handle the extreme conditions found in manufacturing, automotive, aviation, and heavy industrial environments.

These products work by breaking the molecular bonds that allow grease and oil to cling to surfaces. Depending on their chemical composition, they accomplish this through various mechanisms: dissolving oils, emulsifying them into water-washable solutions, or chemically breaking down their structure. The result is that stubborn, baked-on grease that might have accumulated over months or years can be removed, restoring equipment to clean, operational condition.

Industrial degreasers come in various forms—liquids, foams, gels, aerosols, and concentrates—each designed for specific applications and cleaning challenges. They’re formulated to work on different materials (metal, concrete, plastic) and in different conditions (high temperature, food-safe environments, outdoor use).

Types of Industrial Degreasers

The industrial degreaser market offers several distinct categories, each with specific advantages and applications:

Solvent-Based Degreasers

These are the traditional heavy-duty option, using petroleum distillates or synthetic solvents to dissolve grease and oil. They work quickly and effectively on the most stubborn buildups, cutting through layers of contamination that water-based products struggle with.

Solvent degreasers excel in environments where water cannot be used or where immediate evaporation is needed. They’re common in aerospace, electronics manufacturing, and precision machinery cleaning. However, they come with significant drawbacks: strong fumes requiring ventilation, flammability concerns, environmental impact, and potential health hazards with prolonged exposure.

Water-Based (Aqueous) Degreasers

Water-based degreasers use surfactants and detergents to emulsify oils and grease, allowing them to be rinsed away with water. They’re safer for workers, produce fewer volatile organic compounds (VOCs), and are generally more environmentally friendly than solvent-based alternatives.

These degreasers work well for regular maintenance cleaning and moderate grease buildup. They’re popular in food processing facilities, commercial kitchens, and anywhere worker safety and environmental considerations are priorities. The trade-off is that they typically require more dwell time and may need higher temperatures or agitation to match the effectiveness of solvent-based products on heavy contamination.

Citrus-Based Degreasers

Citrus-based degreasers represent a more recent innovation that bridges the gap between effectiveness and environmental responsibility. These products harness d-limonene, a natural solvent extracted from citrus peels (primarily oranges), to dissolve grease and oil without the harsh chemicals found in traditional petroleum-based degreasers.

D-limonene works by penetrating and breaking down the molecular structure of oils and petroleum-based substances. Its chemical properties allow it to dissolve grease while being biodegradable and derived from renewable agricultural waste—the peels left over from orange juice production.

Advantages of Citrus-Based Industrial Degreasers:

Environmental Safety: Citrus degreasers are biodegradable and break down naturally without leaving toxic residues. This makes them suitable for applications where runoff enters wastewater systems or where environmental impact is a concern.

Worker Safety: While proper handling is still required, citrus degreasers are generally less toxic than petroleum solvents. They don’t produce the harsh chemical fumes that require respirators or extensive ventilation, making them safer for workers who use them daily.

Pleasant Scent: Unlike the offensive odors of traditional degreasers, citrus products leave a fresh orange scent. This seems minor but significantly impacts worker willingness to use them and reduces complaints about workplace air quality.

Versatility: Citrus degreasers work on a wide range of applications—from cleaning automotive parts to degreasing industrial equipment, removing adhesives, and even stripping paint. Their effectiveness across multiple tasks can simplify inventory and reduce the number of specialized products needed.

Material Compatibility: Citrus degreasers are safe for most metals, plastics, and painted surfaces, though testing on a small area first is always recommended. They won’t damage materials the way some harsh alkaline or solvent-based products can.

Septic System Safe: In facilities with septic systems or biological wastewater treatment, citrus degreasers won’t kill beneficial bacteria the way harsh chemicals do, making them ideal for rural industrial facilities or food processing plants.

Common Industrial Applications

Industrial degreasers serve countless applications across diverse industries:

Manufacturing and Metalworking: Removing cutting oils, lubricants, and metal working fluids from parts, machinery, and work surfaces. Cleaning stamping presses, CNC equipment, and assembly line machinery.

Automotive and Transportation: Engine degreasing, undercarriage cleaning, parts washing before assembly or painting, cleaning shop floors and work bays.

Food Processing: Cleaning production equipment, removing animal fats from processing lines, maintaining commercial kitchen equipment, degreasing ventilation hoods and exhaust systems.

Aviation and Aerospace: Precision cleaning of aircraft components, removing hydraulic fluids and fuels, maintaining ground support equipment.

Marine Applications: Engine room cleaning, removing diesel residue, maintaining deck equipment exposed to saltwater and petroleum products.

Facilities Maintenance: Cleaning warehouse floors, loading docks, garage areas, and equipment storage facilities where grease and oil accumulate.

Choosing the Right Industrial Degreaser

Selecting an appropriate degreaser requires considering multiple factors:

Type of Contamination: Light oil versus heavy grease versus carbon deposits requires different chemistry. Food-grade oils respond differently than synthetic lubricants.

Surface Material: What works on steel might damage aluminum. Plastic components require compatible products. Painted surfaces need non-aggressive formulations.

Environmental Constraints: Wastewater disposal regulations, VOC restrictions, and environmental policies may dictate product selection. Food processing facilities need NSF-certified products.

Safety Requirements: Confined spaces, poor ventilation, and worker exposure all favor less toxic options like water-based or citrus degreasers over aggressive solvents.

Cleaning Method: Spray-and-wipe applications differ from immersion tanks or pressure washing systems. Application method influences product selection.

Budget: While concentrated products seem expensive per gallon, dilution ratios mean cost per use may be lower than cheaper ready-to-use products.

Application Best Practices

Effective degreasing requires more than just product selection:

Pre-cleaning: Remove loose debris and surface contamination before applying degreaser. This prevents you from trying to clean through layers of dirt that block the degreaser from reaching the grease.

Proper Dilution: Follow manufacturer recommendations precisely. Too weak won’t clean effectively; too strong wastes product and may damage surfaces.

Adequate Dwell Time: Let the degreaser work. Rushing to rinse before the product has time to penetrate and break down grease reduces effectiveness dramatically.

Agitation: Scrubbing, brushing, or using pressure washing helps mechanical action supplement chemical action, especially for heavy buildup.

Temperature Management: Warm degreasers and/or warm surfaces improve performance. Many industrial degreasers work best at 120-140°F.

Thorough Rinsing: Complete removal prevents residue that can interfere with subsequent operations like painting or assembly.

Safety Protocols: Always wear appropriate PPE—gloves, eye protection, and respiratory protection if required. Ensure adequate ventilation and follow all safety data sheet (SDS) recommendations.

Environmental and Regulatory Considerations

Industrial degreaser use is increasingly regulated due to environmental and health concerns:

VOC Regulations: Many jurisdictions restrict volatile organic compound emissions. This has driven demand for low-VOC water-based and citrus degreasers over traditional solvents.

Wastewater Discharge: Used degreasers containing oils and chemicals must be properly disposed of according to local regulations. Some facilities require oil-water separators or pre-treatment before discharge.

Worker Safety: OSHA regulations govern exposure limits and require proper labeling, training, and protective equipment for industrial cleaning chemicals.

Green Certifications: Products with EPA Safer Choice, Green Seal, or similar certifications meet stringent environmental and health standards, helping facilities meet sustainability goals.

The trend is clearly toward safer, more environmentally responsible products that still deliver industrial-strength cleaning. This has accelerated adoption of citrus-based, bio-based, and water-based degreasers that would have been considered inadequate for industrial use a generation ago.

The Future of Industrial Degreasing

Innovation continues in the industrial degreaser market, driven by regulatory pressure, environmental concerns, and demand for safer products:

Bio-based Solvents: Beyond citrus, other plant-derived solvents from soybeans, corn, and other crops are being developed to replace petroleum solvents.

Enzyme-based Cleaners: Biological enzymes that break down specific types of oils and greases offer targeted cleaning with minimal environmental impact.

Smart Formulations: Products that change color when they’ve completed their work, or that indicate when dilution ratios are correct, help users optimize effectiveness and reduce waste.

Concentrated Formats: Ultra-concentrated products reduce packaging, shipping costs, and storage space while giving users control over dilution for specific applications.

Improved Performance: Advances in surfactant chemistry mean water-based products now match or exceed performance that once required harsh solvents.

Conclusion

Industrial degreasers are essential tools in modern manufacturing, maintenance, and industrial operations. From traditional solvent-based products to innovative citrus-based formulations, today’s market offers solutions for virtually every degreasing challenge while increasingly balancing performance with safety and environmental responsibility.

Citrus-based degreasers, in particular, represent a significant advance—proving that effective industrial cleaning doesn’t require sacrificing worker safety or environmental stewardship. As regulations tighten and corporate sustainability commitments grow, products that harness natural solvents like d-limonene are likely to capture increasing market share from traditional chemical degreasers.

The key to effective industrial degreasing isn’t just selecting the strongest product available—it’s matching the right chemistry to the specific application, using proper techniques, and considering the full spectrum of performance, safety, cost, and environmental factors. Whether you choose a traditional solvent, a water-based cleaner, or a citrus-based degreaser, understanding what these products are and how they work ensures you can keep your facility clean, your equipment running, and your workers safe.