The Essential Guide to Lift Station Degreasers

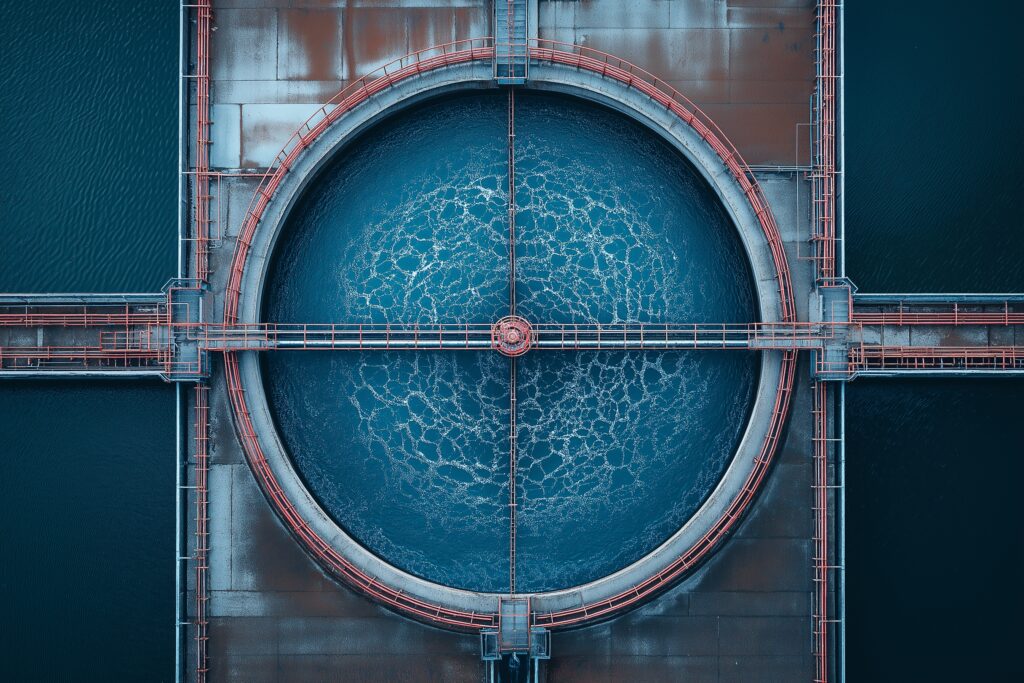

Lift stations play a critical role in wastewater management, ensuring the smooth transportation of sewage from lower to higher elevations. However, these systems often face challenges due to the accumulation of fats, oils, and grease (commonly referred to as FOG). This buildup can lead to blockages, unpleasant odors, and reduced efficiency. Enter lift station degreasers—a vital solution for maintaining the health and functionality of these systems.

What Are Lift Station Degreasers?

Lift station degreasers are specialized cleaning agents designed to break down and dissolve FOG deposits in lift stations, wet wells, and sewer lines. These products typically float on the surface of wastewater, rising and falling with the water levels to clean the walls and prevent grease buildup. They not only enhance the efficiency of lift stations but also help in odor control.

History of Lift Station Degreasers

The history of lift station degreasers is closely tied to the evolution of wastewater management and the need to address challenges like grease buildup and odor control. Here’s a brief overview:

Early Days of Wastewater Management

In the early days of wastewater systems, grease and fat accumulation in lift stations was a persistent issue. Manual cleaning was the primary method for removing these deposits, which was labor-intensive and costly. As wastewater systems became more complex, the need for chemical solutions to address grease buildup became apparent.

Introduction of Chemical Degreasers

The first chemical degreasers were developed to break down fats, oils, and grease (FOG) more efficiently. These early products were often petroleum-based, offering strong cleaning power but raising environmental concerns due to their chemical composition.

Shift to Environmentally Friendly Solutions

With growing awareness of environmental issues, the industry began to shift toward biodegradable and eco-friendly degreasers. Citrus-based and soy-based degreasers emerged as popular alternatives, offering effective grease removal while being safer for the environment.

Modern Innovations

Today, lift station degreasers come in various forms, including floating degreasers, emulsifiers, and bio-blocks. These innovations have made lift station maintenance more efficient and environmentally sustainable.

Floating Lift Station vs. Non-Floating

The primary difference between floating and non-floating lift station degreasers lies in their application method and the way they interact with grease buildup:

Floating Lift Station Degreasers

- Mechanism: These degreasers are designed to float on the surface of the water in a lift station or wet well.

- Action: As the water level fluctuates, the floating degreaser coats the walls and surfaces, dissolving grease and preventing buildup.

- Target: Ideal for addressing grease deposits that accumulate on the walls and upper surfaces of the lift station.

- Advantages: Provides continuous cleaning with each rise and fall of the water, creating a protective layer that is especially effective for maintenance and odor control.

Non-Floating Lift Station Degreasers

- Mechanism: Non-floating degreasers disperse throughout the wastewater rather than remaining on the surface.

- Action: They target grease and fats distributed in the water column and can also address blockages in lower sections of the station or pipes.

- Target: More suitable for cleaning grease that has settled at the bottom or is mixed within the water.

- Advantages: Offers comprehensive cleaning for submerged parts of the system and can address deeper clogs or buildup.

The decision between floating or non-floating lift station degreaser depends on the specific challenges in your lift station:

- If wall grease buildup and odor are primary concerns, floating degreasers are typically more effective.

- For issues like lower-level clogs or grease dispersed throughout the water, non-floating degreasers may be the better choice.

Types of Lift Station Degreasers

- Citrus-Based Degreasers: These are natural and environmentally friendly options that use citrus extracts to dissolve grease. They often leave behind a pleasant citrus scent, making them a popular choice for odor control.

- Petroleum-Based Degreasers: Known for their strong cleaning power, these degreasers are effective but may pose environmental concerns.

- Soy-Based Degreasers: These are biodegradable and long-lasting, making them a sustainable choice for grease removal.

- Specialty Degreasers: Some products offer unique features such as encapsulating odors and providing a refreshing fragrance like grape.

Benefits of Using Lift Station Degreasers

- Prevents Blockages: Regular use of degreasers ensures that FOG does not accumulate, reducing the risk of clogs.

- Odor Control: Many degreasers are formulated to neutralize unpleasant smells, improving the surrounding environment.

- Cost-Effective Maintenance: By preventing grease buildup, degreasers reduce the need for manual cleaning and costly repairs.

- Environmentally Friendly Options: Many modern degreasers are biodegradable and safe for wastewater systems.

How to Use Lift Station Degreasers

- Application: Pour the degreaser directly into the lift station or wet well. The product will float on the surface and begin dissolving grease deposits.

- Coverage: Ensure a 1-2 inch layer of degreaser on the water surface for optimal results. Some products recommend topping off every 2-3 months.

- Continuous Treatment: For ongoing maintenance, some degreasers can be added daily in small quantities to prevent new grease buildup.

Choosing the Right Degreaser

When selecting a lift station degreaser, consider factors such as environmental impact, scent preferences, and the specific needs of your lift station. Products like Citrus all-natural degreaser are ideal for those seeking eco-friendly solutions, while others may prefer the long-lasting effects of soy-based options.

Conclusion

Lift station degreasers are indispensable tools for maintaining the efficiency and hygiene of wastewater systems. By choosing the right product and using it regularly, you can ensure the longevity and optimal performance of your lift station while contributing to a cleaner environment.